Torque converters are known as a vital part of the automatic transmissions of vehicles. Some people consider it complex, but its working is magical once understood. Apart from vehicles, torque converters can be found in several machines. Machines that involve torque will have a torque converter in place. In the industrial sector, there are several machines, such as grinders and many more. Such machines experience a lot of torque. With them being large and operating with large mechanisms, and the industrial torque converter is needed to match the scale.

What is Torque?

Torque in physics is known as the moment of a force. It is the tendency of a force to rotate the body to which it is applied. Torque is found in many aspects of our day to day life. People apply torque when they apply force when using a wrench. It is usually specified with the axis rotation. Torque can occur in different magnitudes, with that of a small magnitude like a wrench being basic. But in big machines, a torque converter might be needed to ensure smooth operations.

Torque Converters and How They Work

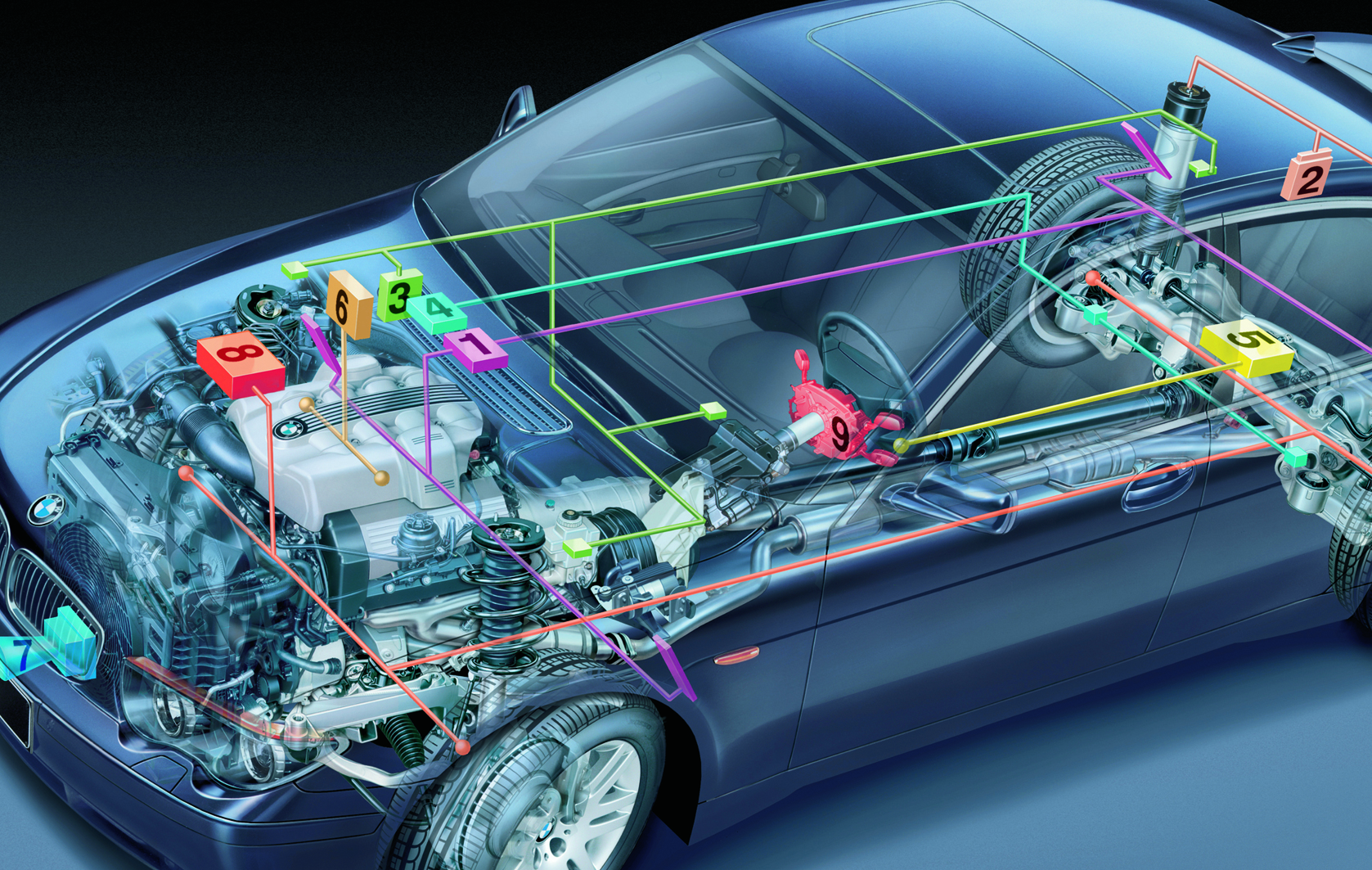

A torque converter is a fluid coupling that transfers the rotating power from a mover to a rotating driven load. In other words, the torque converter connects the power source to the load. Torque converters have three operational phases.

- Stall- at this stage, the prime mover is impelling power on the turbine, but there is no rotation. The stall period is usually brief. It is between when the machine is stationary, and the time it starts to move.

- Acceleration- at this point, the load is moving, but there is a considerable difference between the impeller and turbine speed. Acceleration is where the load starts to gain momentum.

- Coupling- At this stage, the turbine is at about 90% speed of the impeller. At this point, torque multiplication has stopped, and the converter acts as a way of conserving fuel, similar to a regular fluid coupling system.

Functions of An Industrial Torque Converter

Industrial torque converters can be found in conveyor belts, almost all forklifts, construction equipment, and many more. One of the fundamental functions of an industrial torque converter is the smooth shifting of gears. Being responsible for heavy loads, the gears of industrial machines face a lot of pressure. The torque converter ensures that the shifting of gears is made smoother as machines move from a stall to acceleration and later on to coupling.

Industrial torque converters are also crucial in power transmissions of conveyor belts. Industrial machines require a lot of power input for them to work efficiently at peak performance. Seeing a conveyor belt that moves slowly or keeps stalling can be a frustrating site. Industrial torque converters ensure that there is always sufficient power in the belt for it to run smoothly.

It is with no doubt that torque converters are a crucial part of industrial machines. Any industry should ensure that they have the best torque converter to avoid replacement costs and downtime during malfunctions.